Titanium is naturally a high strength, low-density element with excellent corrosion resistance. It is quite ductile and hard, has a high melting point, and has relatively low electrical and thermal conductivity. Read More…

For over 30 years, we have provided metal forged products for a wide variety of industries, including the aerospace, military, food service, medical, and automotive industries. Our customers know they can trust our forgings for quality and affordability.

Although we have over 100 years of experience, we are committed to continually expanding our offerings in all industries. We are not content to remain as we are, but we continually work to improve our products and processes each and every day.

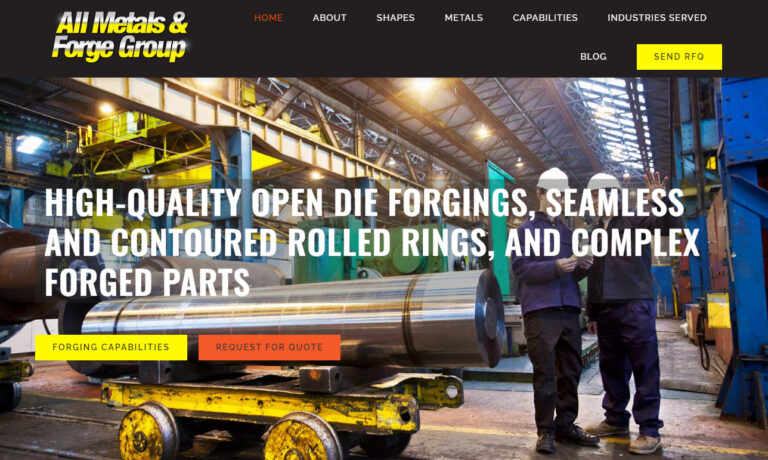

All Metals & Forge Group is your ISO9001:2015 and AS9100D registered forging facility. All Metals provides a wide range of materials, products and services, including discs, shafts, sleeves, cylinders, plates, blocks and many other shapes, both stock and custom, satisfying all of their customers’ requirements. Give All Metals & Forge Group a chance to satisfy your needs— you’ll be glad you...

Welcome to Edgerton Forge, Inc., where we specialize in the production of high-quality forgings for a wide range of industries and applications. With a rich history spanning decades and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the forging industry.

Trenton Forging is a QS 9000 producer of high-quality closed impression die steel forgings including steering and suspension parts, engine parts, construction and mining parts, and many more from carbon and alloy steel. For more information please call Trenton Forging today!

More Titanium Forging Companies

Titanium forgings produce strong, low-density parts similar to carbon steel forging or stainless steel forgings, but about 40% lighter. Titanium forgings offer high resistance to corrosion by salt water, along with a broad range of acids, alkalis, natural waters and industrial chemicals. Titanium forgings come in a variety of shapes, such as rings, cylinders, bars, blocks, discs, sleeves, hubs, flanges, as well as any number of more complex custom shapes for particular applications. Titanium forgings work effectively in environments reaching up to 1000 degrees Fahrenheit.

Because of their excellent strength-to-weight ratio, titanium alloy forgings are used in applications such as engine components and structural components for aircraft, ship components, and valves and fittings for the transportation and chemical industries, where corrosion resistance, optimal strength and low weight are needed.

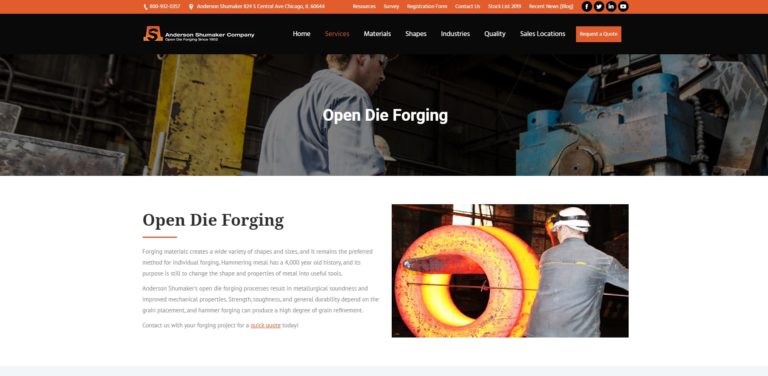

The titanium forging process gives the metal a sophisticated structure that enhances its strength. Most often titanium forgings are created by heating a preformed piece of titanium or titanium alloy and then using a large forging hammer or press that forces the workpiece to take the shape of the die(s). Unlike in casting, the metal is not melted or poured; instead the forging process uses intense pressure to cause the metal to flow into the desired shape.

The process often proceeds gradually through numerous strikes, requiring an operator to move the workpiece through a series of impression cavities. A variety of equipment can be used to forge titanium. Drop forge equipment utilizes a massive drop-hammer that falls from above on the workpiece as it lies on a stationary anvil. In counterblow machines, both the hammer and the anvil move horizontally to impact the workpiece that is held between them.

Forging presses use mechanical or hydraulic force to apply continuous pressure over the course of a number of seconds; the stroke time is much slower than in drop forging, but in most cases only requires one pressing per part. Whatever the particular forging method, titanium forgings make light-weight, high-integrity components capable of performing well even in harsh environments.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services