Metal manufacturing techniques like forging have a lengthy history. The benefit of forging production is that it may enhance the internal structure of the materials and the mechanical qualities in addition to obtaining the shape of mechanical parts. The exceptional performance of aluminum and aluminum alloy has led to its widespread use in various industries, including machinery, electricity, electronics, cars, ships, buildings, instruments, hardware, and home goods. Read More…

For over 30 years, we have provided metal forged products for a wide variety of industries, including the aerospace, military, food service, medical, and automotive industries. Our customers know they can trust our forgings for quality and affordability.

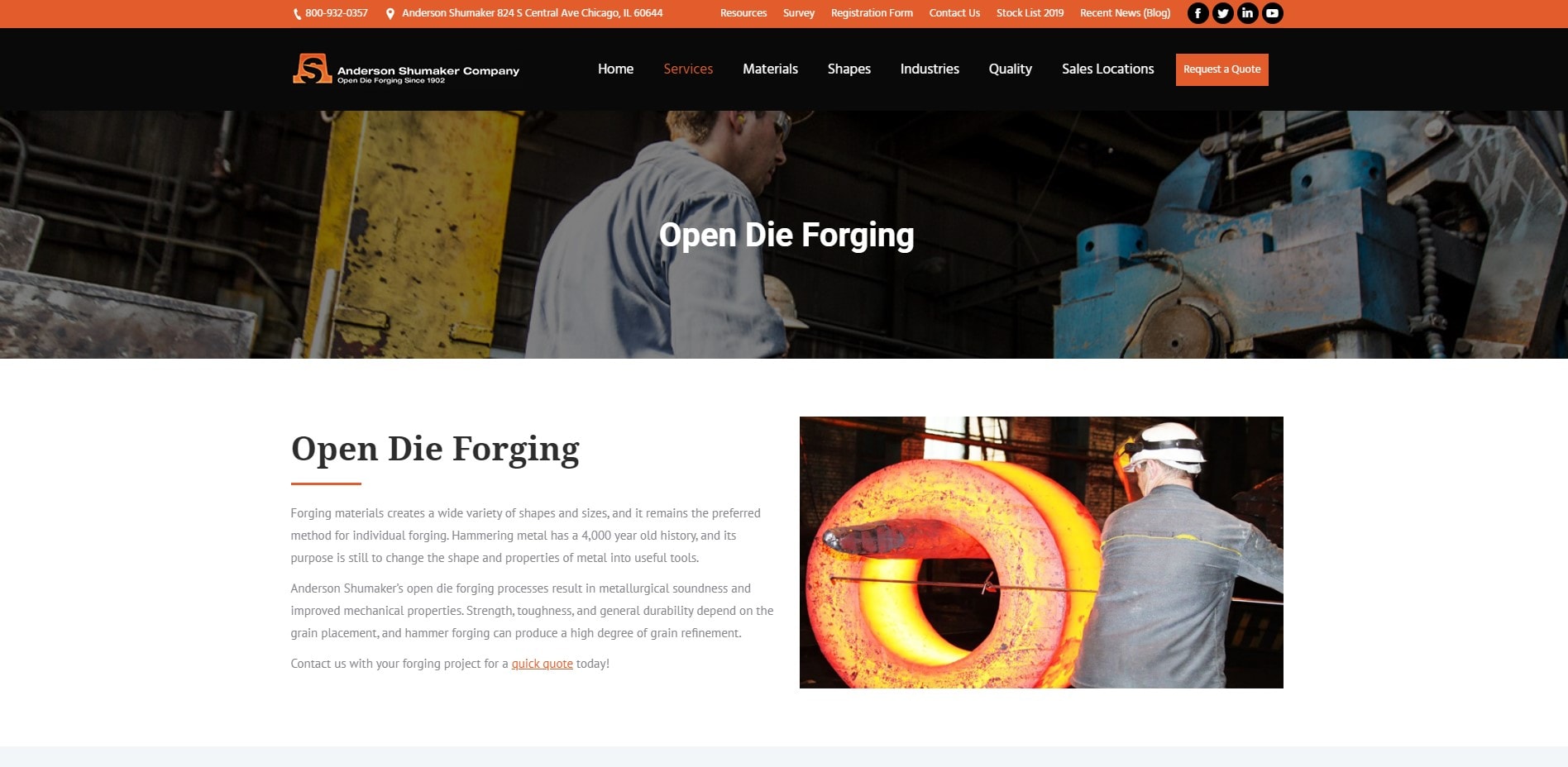

Although we have over 100 years of experience, we are committed to continually expanding our offerings in all industries. We are not content to remain as we are, but we continually work to improve our products and processes each and every day.

All Metals & Forge Group is your ISO9001:2015 and AS9100D registered forging facility. All Metals provides a wide range of materials, products and services, including discs, shafts, sleeves, cylinders, plates, blocks and many other shapes, both stock and custom, satisfying all of their customers’ requirements. Give All Metals & Forge Group a chance to satisfy your needs— you’ll be glad you...

Welcome to Edgerton Forge, Inc., where we specialize in the production of high-quality forgings for a wide range of industries and applications. With a rich history spanning decades and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the forging industry.

Trenton Forging is a QS 9000 producer of high-quality closed impression die steel forgings including steering and suspension parts, engine parts, construction and mining parts, and many more from carbon and alloy steel. For more information please call Trenton Forging today!

More Aluminum Forging Companies

As a result, aluminum forging is mostly used to create significant mechanical parts with strong mechanical qualities and big bearing capacities. For example, forgings made of aluminum make up 77% of aircraft's weight, 68% of tanks, and 76% of automobiles.

Aluminum alloy is frequently used in forging. All goods forged with low-carbon steel can be substituted by aluminum forging, which holds a significant position in the industrial sector. Most forged aluminum components are safety components produced in huge quantities, so the internal quality of aluminum materials must meet stringent standards.

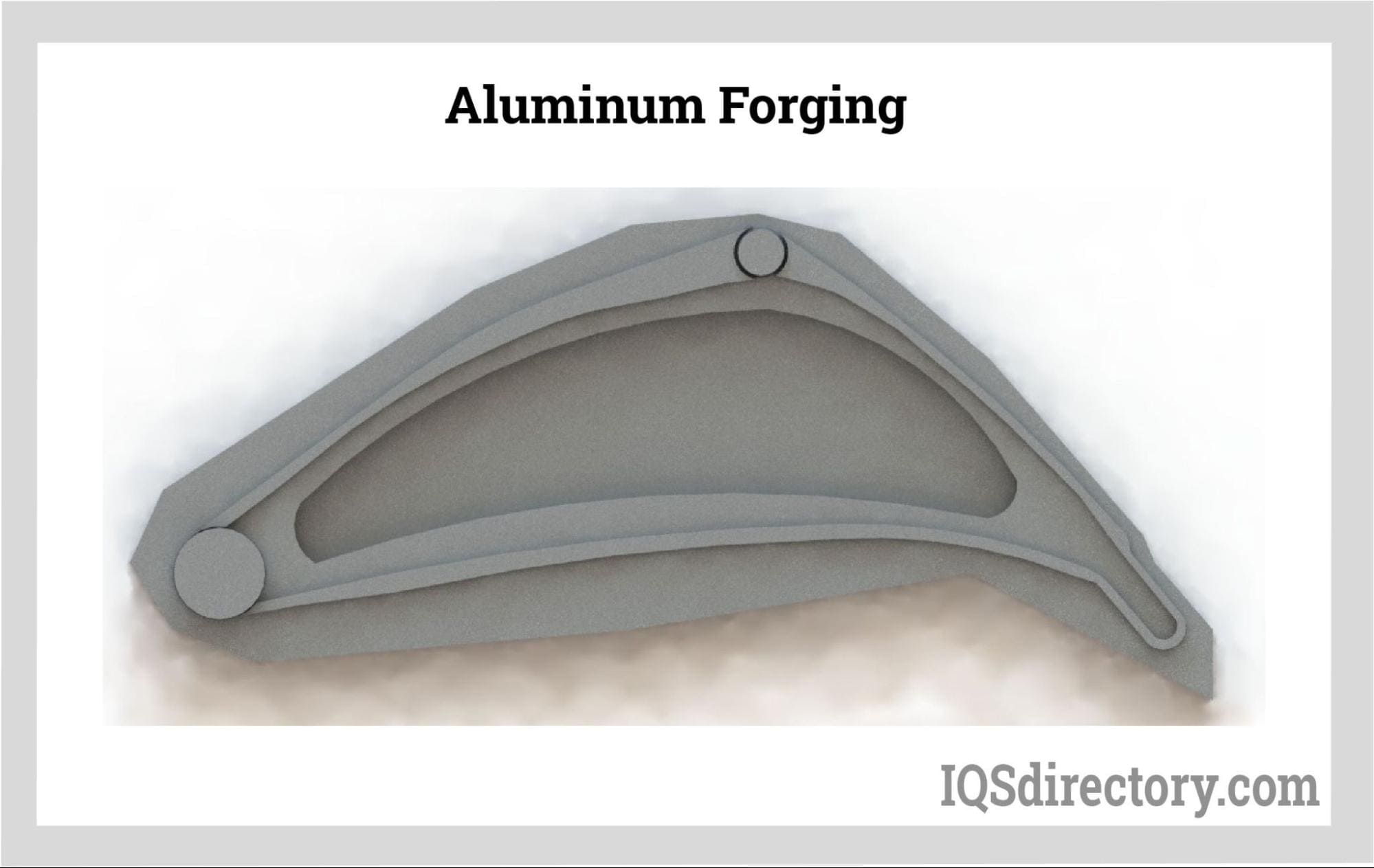

Aluminum is formed into a certain shape using a compressive force, and the finished item is called an aluminum forging. The aluminum's grain structure changes throughout the forging process to take on the appropriate shape. Since the metal has been strengthened, the product is significantly stronger than if manufactured through fabrication, casting, or welding.

Manufacturing Process of Aluminum Forgings

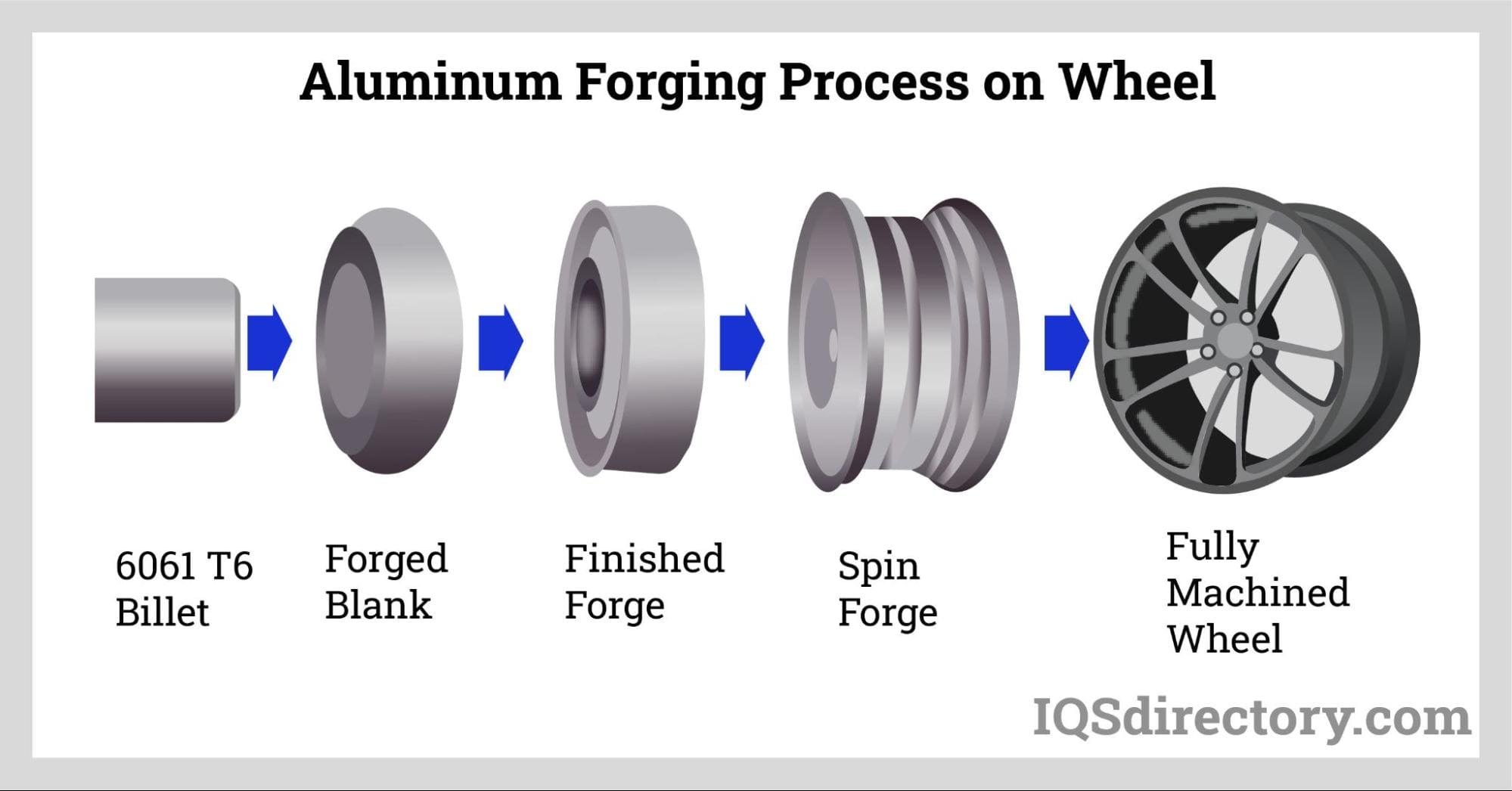

A cast or extruded piece of aluminum is heated during the forging process and is then pressed or hammered into the shape of a die. In contrast to casting, this method uses tremendous pressure to shape the die when the metal is melted and poured. However, hot forging is one technique that can produce aluminum pieces that can weigh up to 25 tons.

As an alternative, cold forging involves hammering or pressing aluminum pieces into a die at temperatures ranging from ambient temperature to several hundred degrees Fahrenheit. Because the finished product's crystalline structure conforms to the component's shape during the cold forging process, it becomes even stronger. Regardless of the method, aluminum forging increases the material's mechanical qualities, such as its strength, while also reducing its size.

Applications of Aluminum Forgings

Because of its strength-to-weight ratio, low production cost, low density, and ability to withstand the harsh conditions of space, aluminum forgings are commonly employed in industries where weight is an issue, such as aerospace. Because aluminum-forged wheels are lightweight, tough, and sturdy, the competitive racing sector is another area that uses aluminum forging. Aluminum forged wheels are utilized in several models from companies like Lamborghini®, Audi®, and Porsche® that aren't race cars.

Ships, tractors, engines, oil drilling equipment, and missiles are a few more things that regularly use aluminum forgings. The standard configurations for aluminum forgings include flanges, hubs, sleeves, disks, blocks, bars, cylinders, and rings. A lot of businesses also provide customization services.

Advantages of Aluminum Forgings

Strength

Aluminum forgings that have been forged and heat-treated have some mechanical characteristics similar to those of steel forgings. As a result, the strength-to-weight ratio is much better. For instance, the 2014-T6 aluminum forging has an average UTS of 485MPa, higher than all frequently used aluminum castings and many grades of steel forgings.

Forging is always free of porosity, in contrast to casting, which enables relatively simple heat treatment procedures that dramatically enhance a few mechanical qualities. The more affordable 6061 aluminum forging achieves typical values of 310MPa, which is better than, for instance, semi-solid cast, squeeze cast, or gravity cast A356 (or 601 types) aluminum casting. With 6061 aluminum, additional welding fabrication is possible, making it suitable for various uses.

Cost

The cost will be a key deciding element once multiple manufacturing processes are viable from a functional standpoint. In general, aluminum forging tooling is less expensive and has a higher production rate than aluminum die-casting tooling. However, raw materials must be alloyed to produce appropriate heat-treatable qualities, resulting in higher raw material costs. As a result, although this is only sometimes the case, many aluminum forgings are employed in highly stressed applications.

Surface Quality

With forging, a wide range of surface finishes, from extremely smooth surfaces to reasonably sharp serrations, can be created. This variety may help with further surface finishing or be a useful feature of the part design. In addition, some alloys, like 6061, have advantageous anti-corrosion properties without any further surface treatment.

Environmental Benefits

Metal fabrication and production demand a lot of energy and chemicals. These procedures are not environmentally friendly as a result. Many aluminum forging plants have found and put into practice methods to make their manufacturing process "greener." One action they have taken is recycling waste products. If a business decides to use recycled scrap metal instead of fresh aluminum, the expenses of buying and shipping the metal might be significantly reduced as well.

Choosing the Right Aluminum Forging Manufacturer

To ensure the most productive outcome when purchasing aluminum forgings from an aluminum forging manufacturer, it is important to compare several companies using our directory of aluminum forging manufacturers. Each aluminum forging manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each aluminum forging business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple aluminum forging companies with the same form.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services