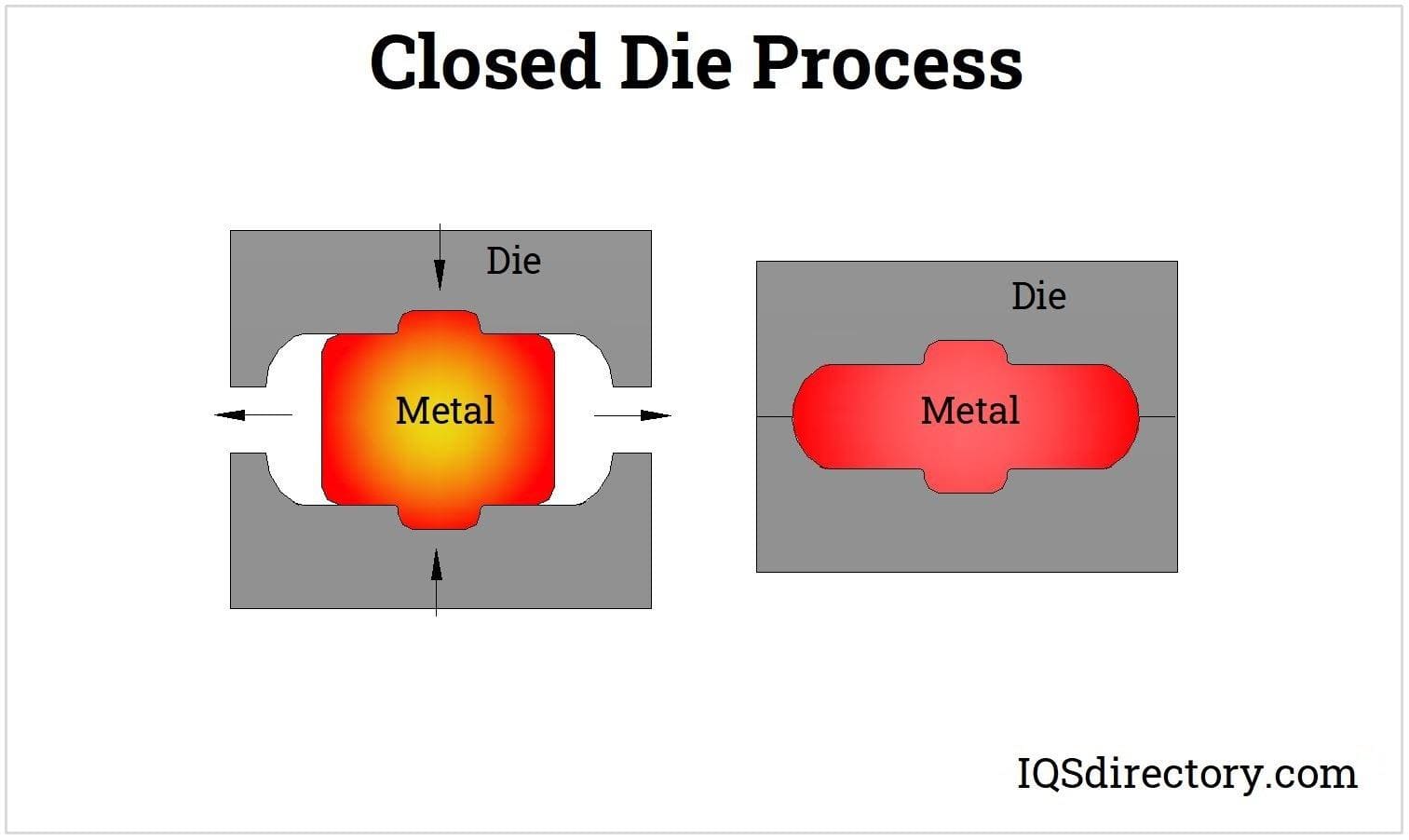

Closed die forging is hammering or pressing prepared metal blanks into a die shaped like the final product. The hammer and anvil entirely envelop the piece, forcing the metal to conform to the die completely. Read More…

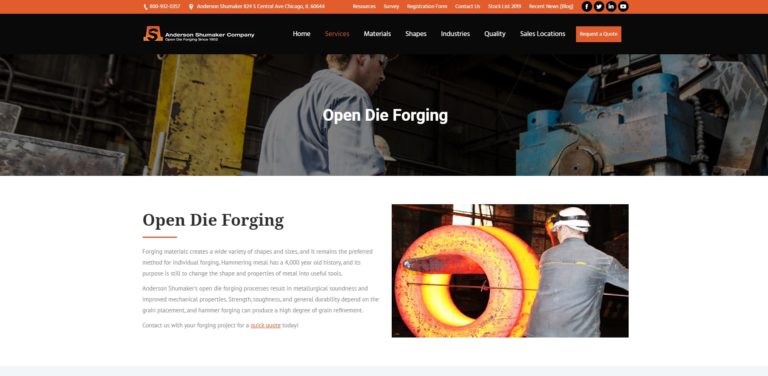

For over 30 years, we have provided metal forged products for a wide variety of industries, including the aerospace, military, food service, medical, and automotive industries. Our customers know they can trust our forgings for quality and affordability.

Although we have over 100 years of experience, we are committed to continually expanding our offerings in all industries. We are not content to remain as we are, but we continually work to improve our products and processes each and every day.

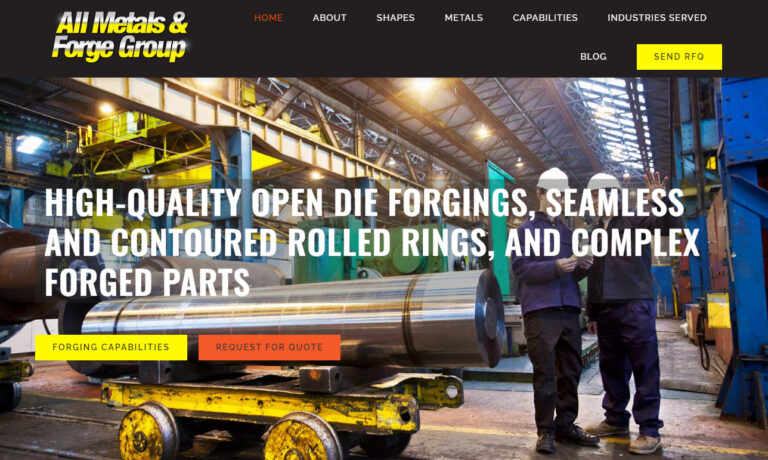

All Metals & Forge Group is your ISO9001:2015 and AS9100D registered forging facility. All Metals provides a wide range of materials, products and services, including discs, shafts, sleeves, cylinders, plates, blocks and many other shapes, both stock and custom, satisfying all of their customers’ requirements. Give All Metals & Forge Group a chance to satisfy your needs— you’ll be glad you...

Welcome to Edgerton Forge, Inc., where we specialize in the production of high-quality forgings for a wide range of industries and applications. With a rich history spanning decades and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the forging industry.

Trenton Forging is a QS 9000 producer of high-quality closed impression die steel forgings including steering and suspension parts, engine parts, construction and mining parts, and many more from carbon and alloy steel. For more information please call Trenton Forging today!

More Closed Die Forging Companies

What is Closed Die Forging?

Closed forging is distinct from open die forging, in which the die contacts only a portion of the piece at a time. Closed die forging can produce complicated designs with strict tolerances, and the number of conceivable shapes is virtually limitless.

How Closed Die Forging Works

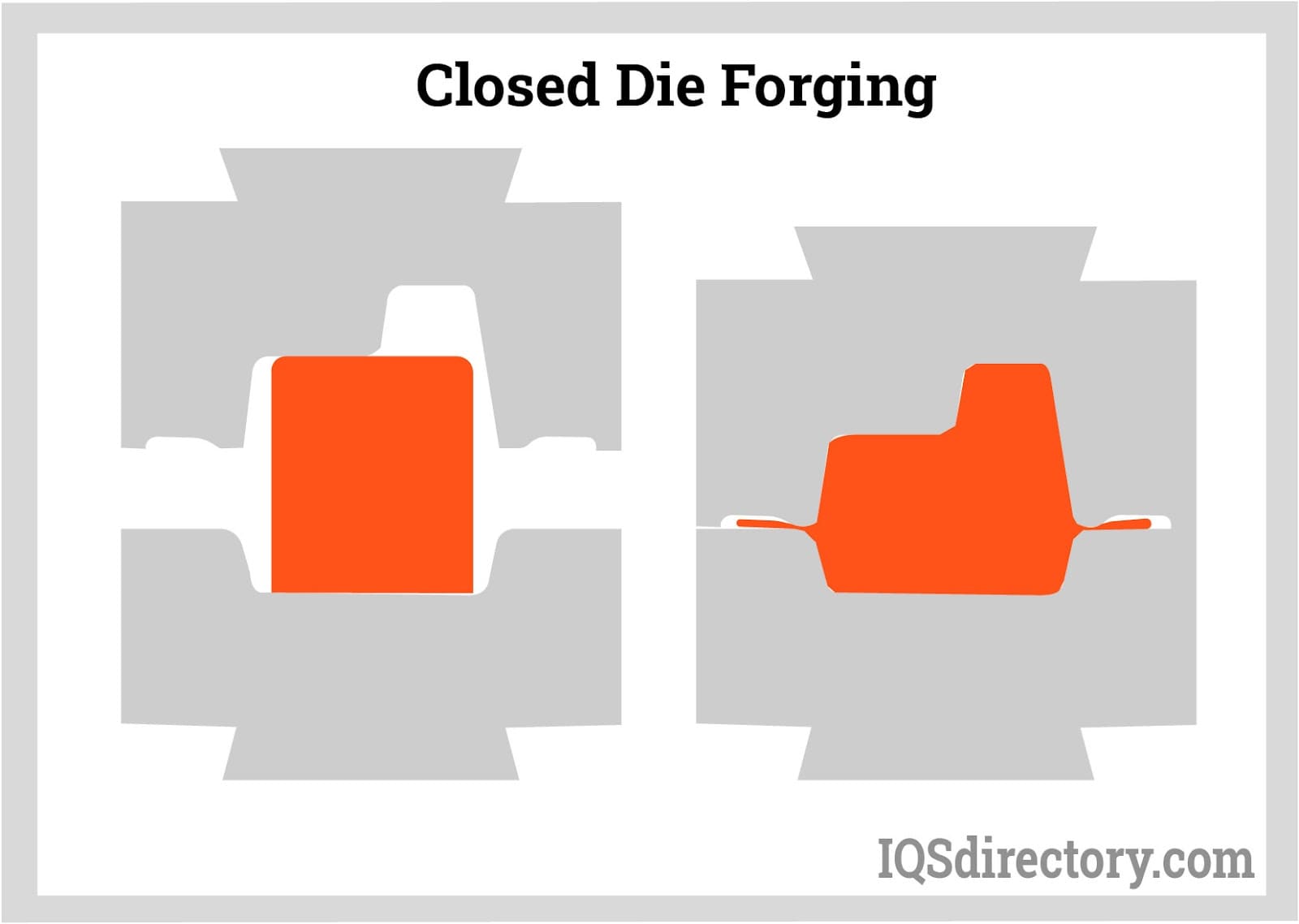

Closed die forging occurs when metal is placed in a die that looks like a mold and is attached to an anvil. After that, the hammer is slammed against the workpiece, causing the metal to flow and fill the die cavities. The hammer makes repeated contact within milliseconds. The hammer may descend numerous times in rapid succession, depending on the size and complexity of the part. Surplus metal may be forced out of the die cavities, referred to as flashing.

Because the flash cools faster than the rest of the material and is usually stronger than the metal in the die, it helps to prevent the formation of new flash. The flash also forces the metal to fill the die cavity completely; the contents are removed following forging. The workpiece is normally pushed through a succession of cavities in a die to get from ingot form to final form in commercial closed die forging. The first impression is used to distribute the metal into a rough shape according to the material later required in the cavities.

An edging, fullering, or bending impression is a type of imprint. After that, the piece is manipulated into a shape that looks more like the final result, called blocking cavities. These steps frequently result in big filets and generous bends in the workpiece. In a finisher or final cavity, the final shape is forged. If the parts are only being produced in small quantities, it may be more cost-effective to skip the final imprint cavity and machine the part instead.

Types of Closed Die Forging

The different types of closed die forging include:

Cold Die Forging

The metal is forged using high pressure rather than direct heat in the cold forging method. Dies are typically round, greased, and kept at room temperature. Carbon and standard alloy steel forgings are common cold-forged materials. Cold forging has a high production rate, a safer working environment, a long die life, and improves the metal’s mechanical qualities.

Warm Die Forging

Steel alloys are ideal for the heated forging process. The typical temperature ranges from above room temperature to 1800 degrees Fahrenheit (982.2 °C) depending on the alloy. Warm forging allows producers to make complicated forms. Warm forging reduces tooling stresses, improves steel ductility, and removes the need to anneal or heat-treat the metal before forging. However, warm forging has some drawbacks, including temperature control restrictions and the need for heating equipment.

Hot Die Forging

Heat is transported from the workpiece to the die during the hot forging process, resulting in thermal gradients in the workpiece. The hot forging process is commonly used on titanium alloys, aluminum alloys, nickel alloys, and steel. Temperatures can range from 1700 to 2300 °F (925 to 1260 °C) depending on the metal.

Advantages of Closed Die Forging

- In contrast to investment casting, the initial costs of forging dies for producing metal components in closed die forging are fairly high. Nevertheless, if the parts are produced in large quantities, it is the most cost-effective metal-forming method due to the cheap cost of each part.

- During the closed die forging process, the interior grain of the workpiece is refined, and the mechanical properties of closed die forged parts, particularly their strength, is increased. When it comes to lifting and rigging hardware, closed die forging is the clear winner regarding safety and strength.

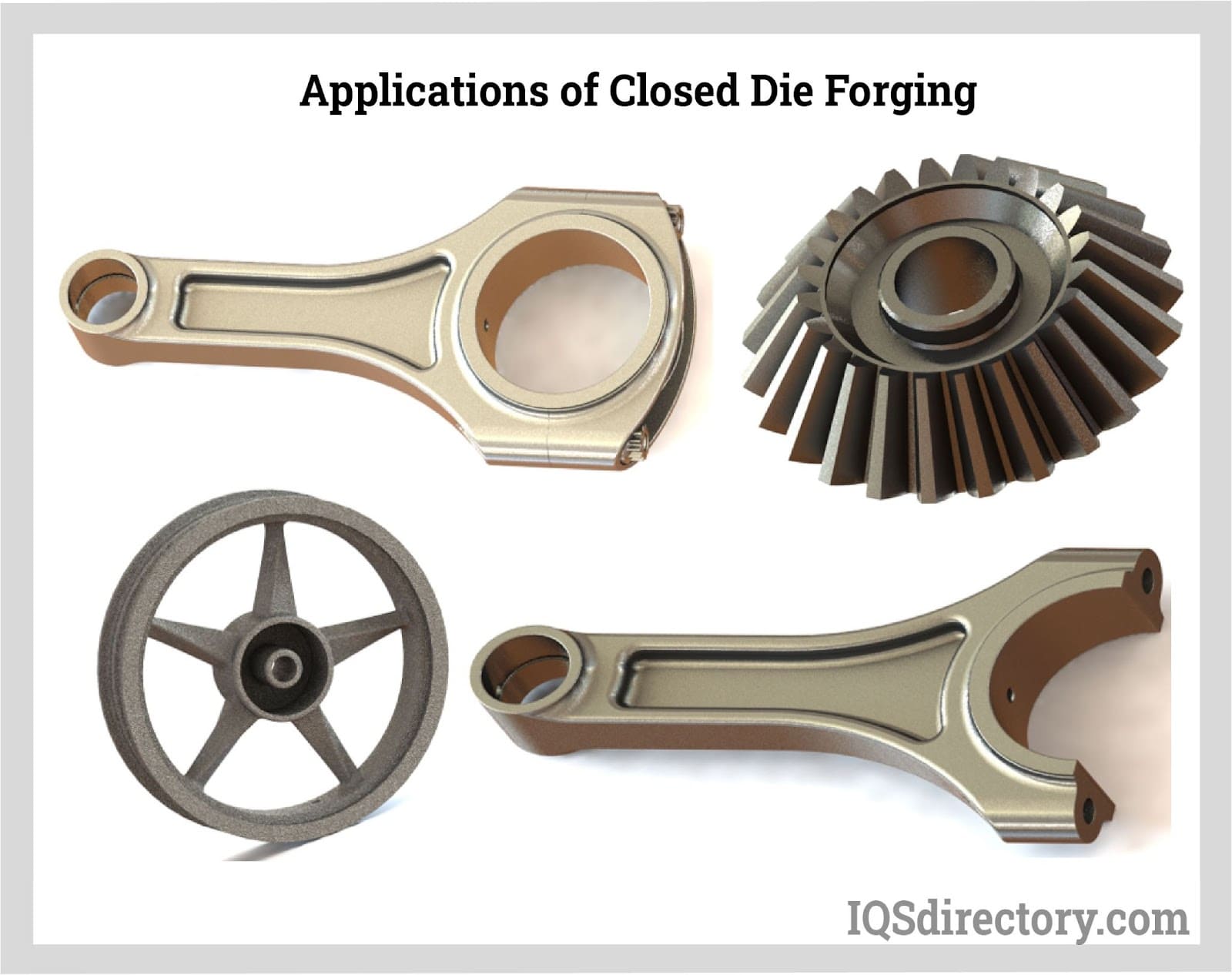

Applications of Closed Die Forging

- Steel and aluminum components are mostly produced via closed die forging. As a result, closed die forging has a wide range of applications. Mining drilling bits, forestry wear parts, agricultural wear parts, construction wear parts, rigging and lifting components, and so on might all be made with it. In a nutshell, any application that requires high-quality components might use this approach.

- Closed die forging may produce symmetrical and asymmetrical pieces from various materials.

Choosing the Right Closed Die Forging Manufacturer

To ensure the most positive outcome when purchasing closed die forgings from a closed die forging manufacturer, it is important to compare several companies using our directory of closed die forging manufacturers. Each closed die forging manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each closed die forging business website using our patented website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple closed die forging manufacturers with the same form.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services