Ring forging, also known as roll forming, is a forging technique that involves shaping a metal object with opposing rollers. Although roll forging uses rolls to achieve material deformation, it is a discrete process, not a continuous one, analogous to metal forging rather than metal rolling. Read More…

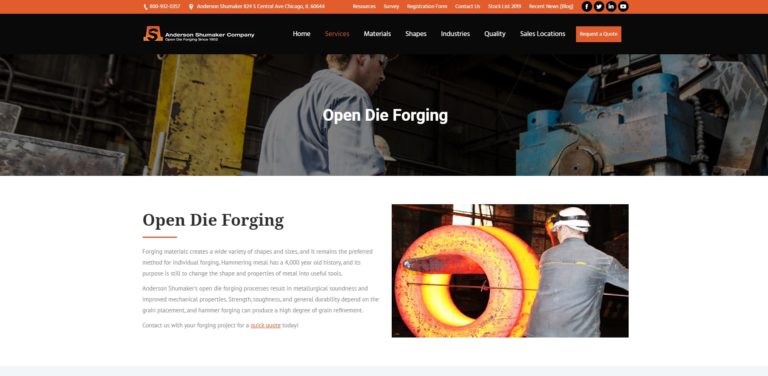

For over 30 years, we have provided metal forged products for a wide variety of industries, including the aerospace, military, food service, medical, and automotive industries. Our customers know they can trust our forgings for quality and affordability.

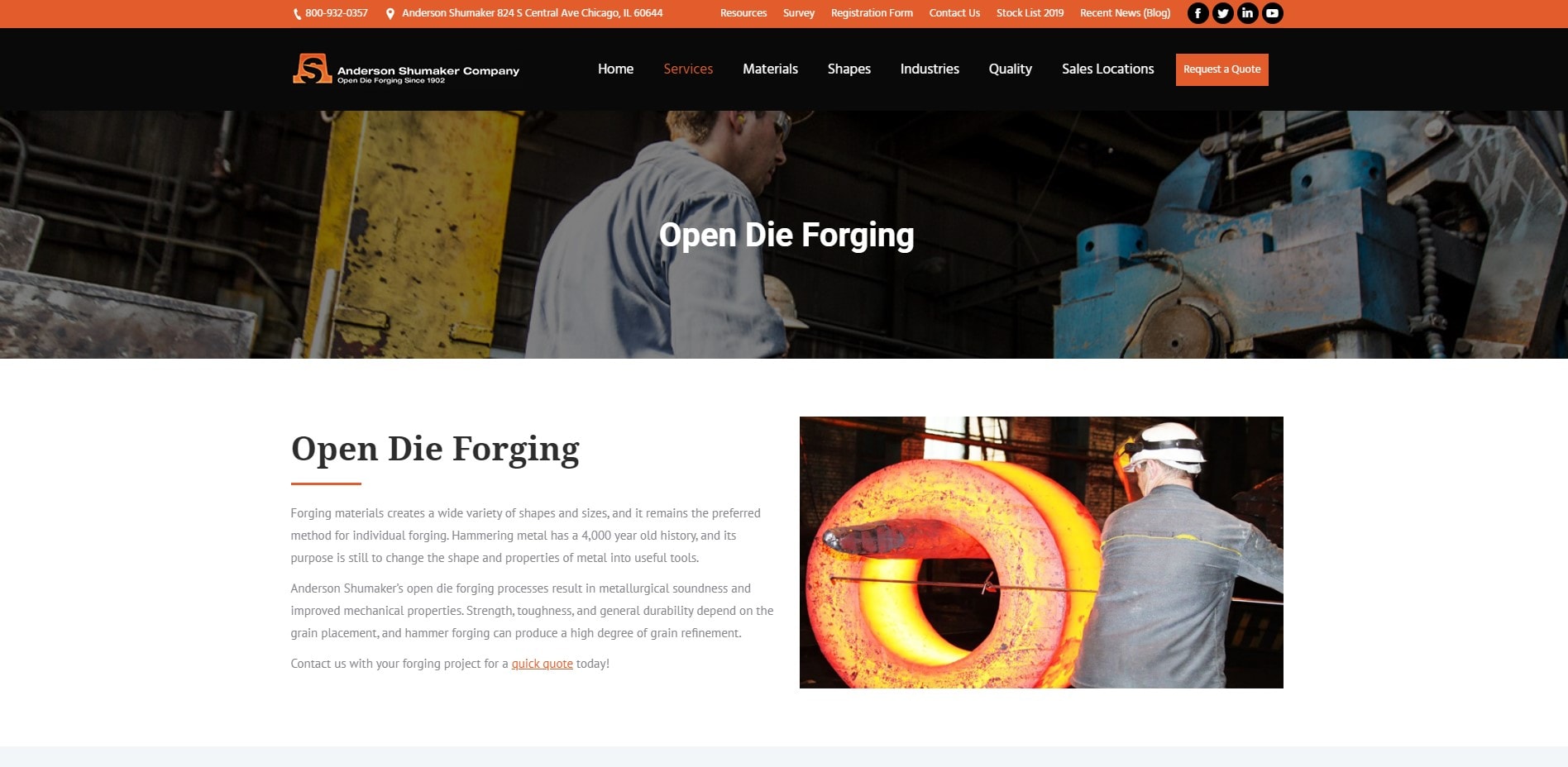

Although we have over 100 years of experience, we are committed to continually expanding our offerings in all industries. We are not content to remain as we are, but we continually work to improve our products and processes each and every day.

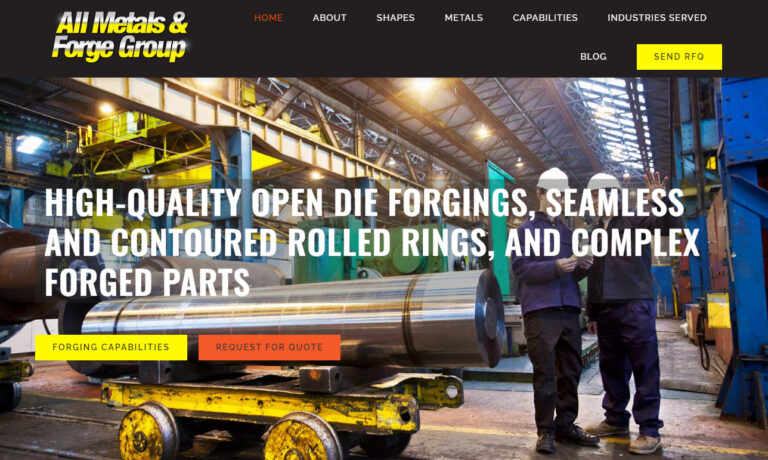

All Metals & Forge Group is your ISO9001:2015 and AS9100D registered forging facility. All Metals provides a wide range of materials, products and services, including discs, shafts, sleeves, cylinders, plates, blocks and many other shapes, both stock and custom, satisfying all of their customers’ requirements. Give All Metals & Forge Group a chance to satisfy your needs— you’ll be glad you...

Welcome to Edgerton Forge, Inc., where we specialize in the production of high-quality forgings for a wide range of industries and applications. With a rich history spanning decades and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the forging industry.

Trenton Forging is a QS 9000 producer of high-quality closed impression die steel forgings including steering and suspension parts, engine parts, construction and mining parts, and many more from carbon and alloy steel. For more information please call Trenton Forging today!

More Ring Forging Companies

What is Ring Forging?

Ring forging is frequently done in a heated environment. The roll's grooves are carefully designed to forge the part to the desired dimensions.

The forging geometry of the rings used to forge metal items is only visible on a small fraction of the diameter of the ring. Only a portion of a full ring revolution is required to forge the workpiece.

The forging geometry on the rings in the industrial business often takes up one-quarter to three-quarters of the ring's circumference.

Ring Forging Process

The initial step in the roll forging process is to upset a billet, which is usually a cylinder. Upsetting prepares the workpiece by deforming it to the required diameter, height, and shape and expanding its cross-section. This deforming method applies a lot of pressure to the workpiece, which is exerted horizontally by a hydraulic press.

The upsetting dies compress the workpiece while it is still at its plastic deformation temperature, allowing it to spread outside the press. It's an open die method in which an upper and lower die press the cylinder, and it can be done hot or cold. Upsetting the workpiece helps it to keep its grain structure, which is a common side effect of the forging process.

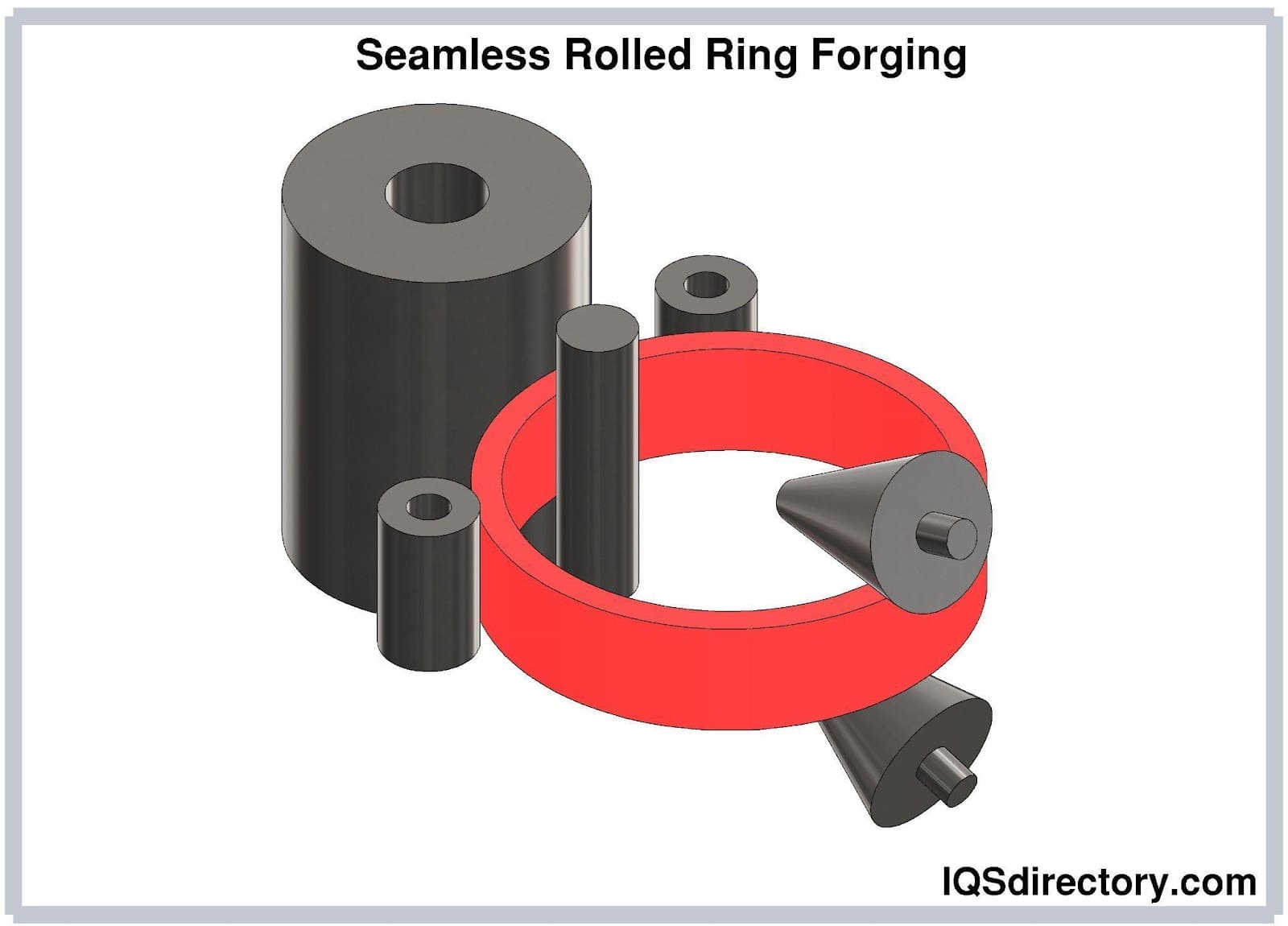

The center of the workpiece must be removed in seamless rolled ring forging. This stage of the process is known by various names, including punching. Piercing results in the formation of a circular donut shape.

Piercing does not involve drilling into the workpiece; instead, a punch is used to significantly displace the metal, leaving a thin web at the bottom of the punched aperture.

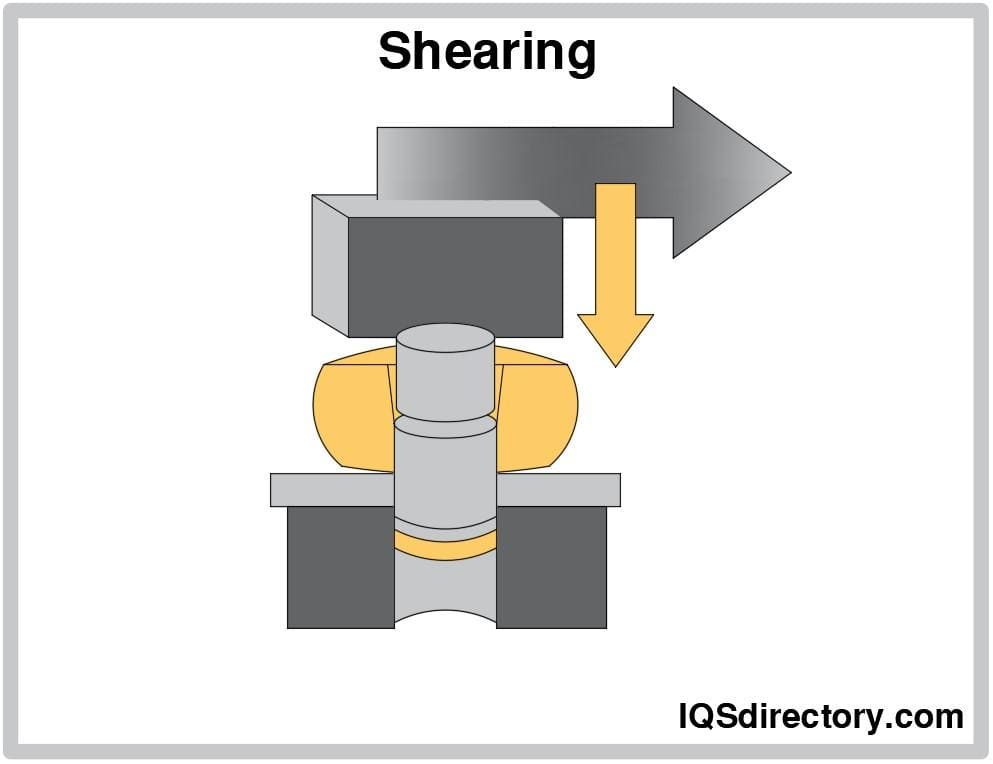

The piercing process is completed by shearing, which eliminates the web of metal at the bottom of the pierced hole. Then, to prepare for the rolling ring forging process, the outcome is a finished hole that runs completely through the workpiece.

The piercing and shearing procedures make a hole in the workpiece large enough to fit over the mandrel, a blunt end rod used to shape the donut hole. Steel or medium carbon steel mandrels are used. The workpiece is heated slightly below its recrystallization temperature before being placed over the mandrel.

The rotation of the prepared donut shape starts the shaping process. The mandrel imparts pressure to the interior of the donut as it rotates, pressing it against the main roller. The workpiece's diameter and walls thin as a result of the rotation and pressure.

The axial rollers reduce the height of the workpiece's cross-section as the mandrel and main roller increase the diameter and thin the walls of the workpiece. The workpiece's rotation by the main roller and mandrel, as well as the action of the axial rollers, is constant and progressive, preserving the grain formation of the workpiece.

The workpiece continues to rotate and shape until the correct dimensions are obtained. Because no cutting, welding, or forging is involved in the shaping and forming of the finished item, this method is known as seamless rolling ring forging.

Throughout the procedure, the object stays a solid single metal component.

Applications of Ring Forging

Wind turbines

Seamless rolling ring forged pieces can be found in every element of a wind turbine. They are an important component of wind turbine design. Seamless rolling ring forged parts are great for keeping wind turbines operating and productive because of their accuracy, precision, and strength.

Automotives

Several portions of a vehicle must survive high loads and stress, necessitating the usage of components that can withstand the conditions to keep the vehicle functioning. Every portion of a truck or car contains seamless rolled ring forged components and pieces such as crankshafts, camshafts, clutches, braking systems, gears, and couplings. These high-quality parts can survive the continual wear, pressure, and ripping with normal vehicle operation. They are more lightweight, adaptable, and resistant to constant torque.

Choosing the Correct Ring Forging Manufacturer

To ensure you have the most positive outcome when purchasing ring forgings from a ring forging manufacturer, it is important to compare several companies using our directory of ring forging manufacturers. Each ring forging manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each ring forging business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple ring forging companies with the same form.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services