Carbon steel is a ferrous alloy whose main alloying element is carbon, but it can also contain limited amounts of copper, manganese and silicon. The carbon gives the steel greater hardness and strength, particularly when the steel is heat treated. Read More…

For over 30 years, we have provided metal forged products for a wide variety of industries, including the aerospace, military, food service, medical, and automotive industries. Our customers know they can trust our forgings for quality and affordability.

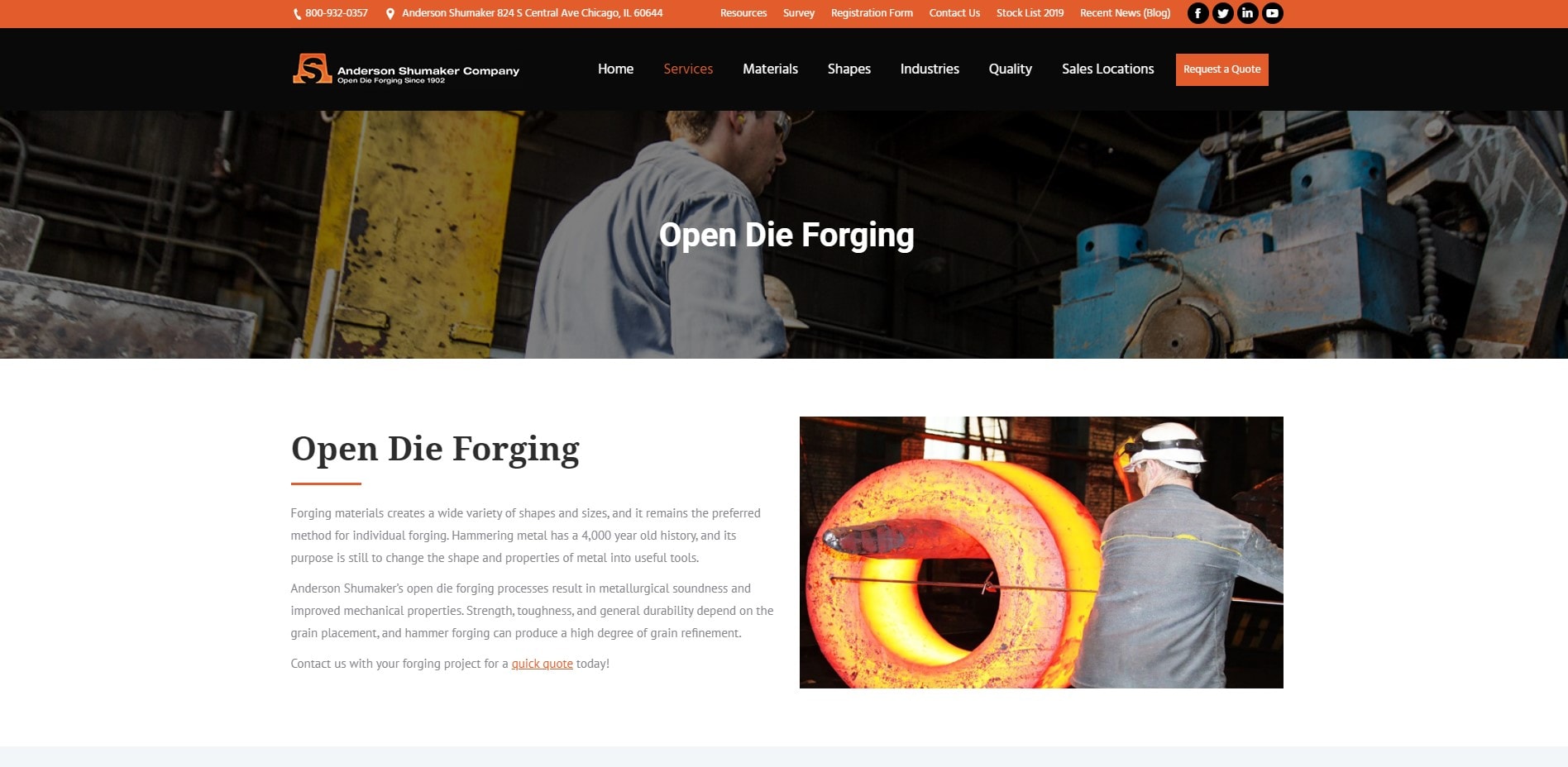

Although we have over 100 years of experience, we are committed to continually expanding our offerings in all industries. We are not content to remain as we are, but we continually work to improve our products and processes each and every day.

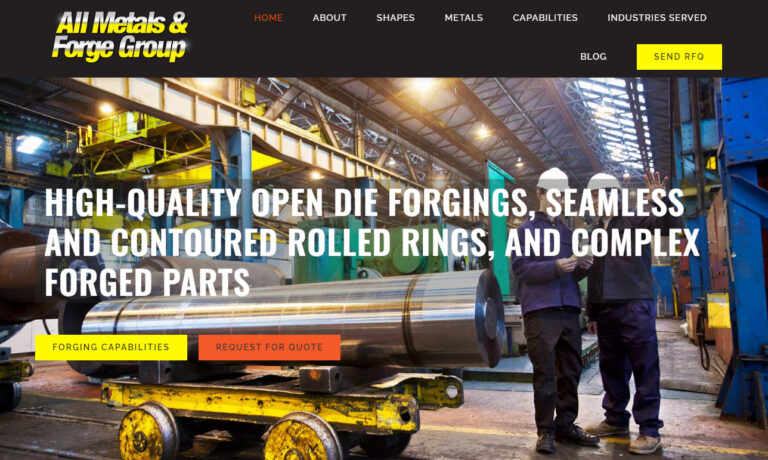

All Metals & Forge Group is your ISO9001:2015 and AS9100D registered forging facility. All Metals provides a wide range of materials, products and services, including discs, shafts, sleeves, cylinders, plates, blocks and many other shapes, both stock and custom, satisfying all of their customers’ requirements. Give All Metals & Forge Group a chance to satisfy your needs— you’ll be glad you...

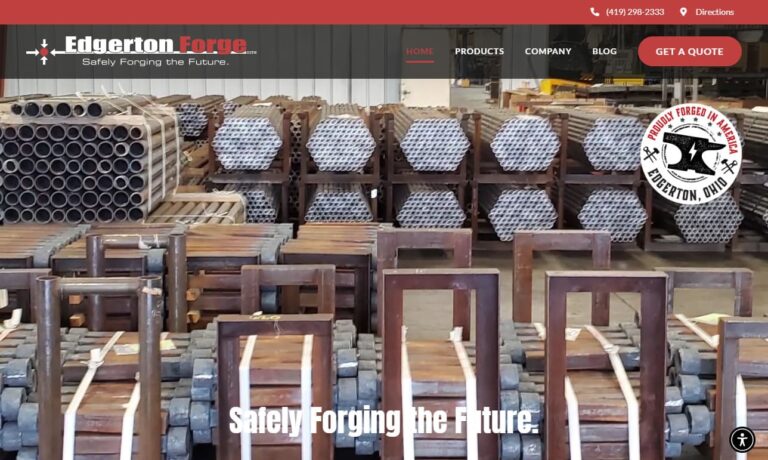

Welcome to Edgerton Forge, Inc., where we specialize in the production of high-quality forgings for a wide range of industries and applications. With a rich history spanning decades and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the forging industry.

Trenton Forging is a QS 9000 producer of high-quality closed impression die steel forgings including steering and suspension parts, engine parts, construction and mining parts, and many more from carbon and alloy steel. For more information please call Trenton Forging today!

More Carbon Steel Forging Companies

Carbon steel is quite malleable, and therefore is easily processed and readily forged. Its varied response to heat treatment also lends it a sort of versatility, with different processing yielding steel with different mechanical properties. The low material cost, adaptability, great strength, and ease of manufacturing of carbon steel forgings have made them prevalent in a variety of industries, including the military, construction, aircraft, aerospace, mining, automotive, chemical, railway, oil and gas, marine, trucking, and defense industries.

Carbon steel forgings are the most common type of forgings in use, serving as industrial components such as blocks, blanks, bars, hubs, disks, flanges, spindles, cylinders, shafts, rings, piping parts and more. Carbon steel forgings are effective in temperatures up to 900°F (482°C).

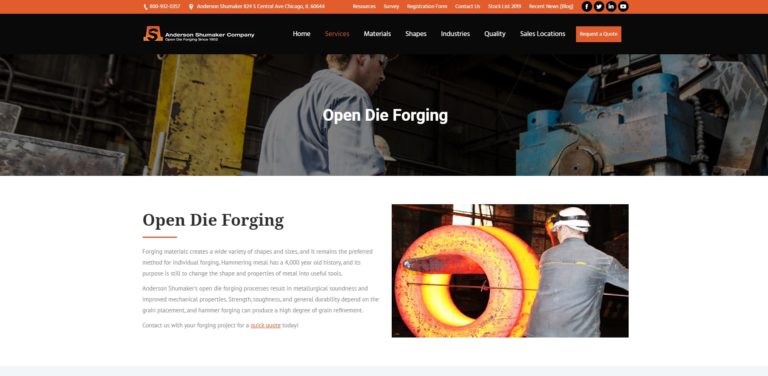

The carbon steel forging process gives the metal a dense, sophisticated structure that enhances the strength and mechanical properties of the steel while slightly reducing its size. Most often carbon steel forgings are created by heating a cast or extruded piece of steel and then using a large hammer or press that forces it to take the shape of a die.

The metal is never melted or poured, as in metal casting. Instead the forging process uses intense pressure to cause the metal to flow into the desired shape. Hot forging is a very adaptable method, capable of forming all sizes and any sort of shape using either and open or a closed die. Larger quantities from 25 pounds up to 25 tons are always forged hot. Cold forging and warm forging are alternate forging techniques in which small quantities of carbon steel ranging from room temperature to a few hundred degrees Fahrenheit are hammered or pressed into a die.

Cold forging and warm forging create an even stronger forged product by a process known as work hardening, in which slight alterations are made in the crystalline structure of the metal to conform to the shape of the part. Whatever the forging method, carbon steel forgings make for high-integrity and cost-effective mechanical and industrial components.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services