Sierra Alloys

Sierra AlloysRequest A Quote

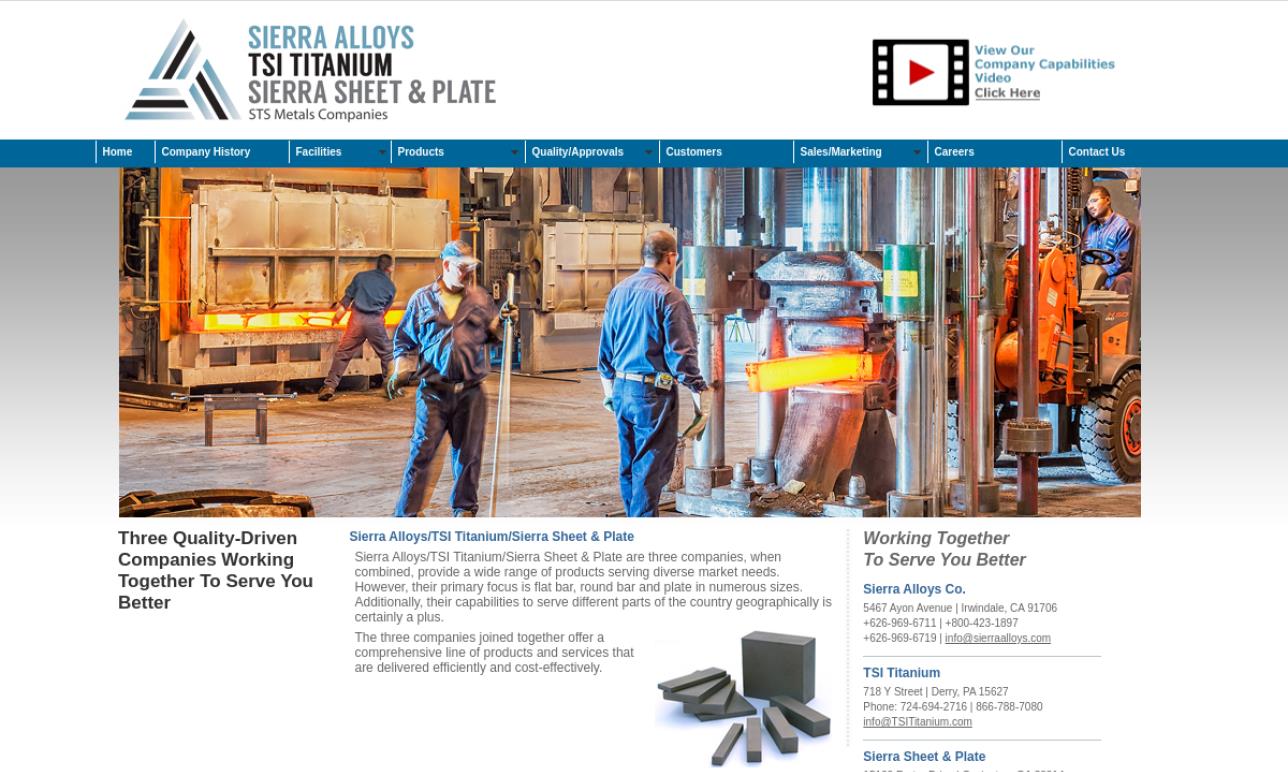

Irwindale, CA | 800-423-1897Sierra Alloys is a leading manufacturer and supplier of high-performance metal products, specializing in the production of forged and rolled rings, discs, and open die forgings. The company has been in business for over 30 years and is headquartered in Irwindale, California. Sierra Alloys is known for its ability to produce high-quality, complex metal components to meet the exacting specifications of its customers. The company's expertise in metallurgy, coupled with its advanced forging and heat-treating capabilities, allows it to produce custom solutions that meet the most demanding requirements of a wide range of industries, including aerospace, defense, medical, and power generation. The company's products include a wide range of alloys, such as titanium, nickel, cobalt, and stainless steel. Sierra Alloys also offers machining, welding, and assembly services to provide customers with a complete, turnkey solution for their metal component needs. One of Sierra Alloys' core strengths is its ability to work with customers to develop custom solutions that meet their specific needs. The company has a team of experienced engineers and metallurgists who work closely with customers to understand their requirements and develop solutions that meet or exceed their expectations. Sierra Alloys' commitment to quality is evident in its ISO 9001:2015 and AS9100D certifications, which attest to the company's adherence to the highest quality standards in the industry. In addition to its extensive manufacturing capabilities, Sierra Alloys is committed to providing exceptional customer service. The company's sales team is knowledgeable and responsive, providing customers with the information and support they need to make informed decisions about their metal component needs. With a commitment to quality, expertise in metallurgy and advanced manufacturing capabilities, Sierra Alloys is a trusted partner for customers looking for custom metal components that meet their specific needs.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services