Metal material parts produced through the forging process are known as forgings. During forging operations, a compressing force pressures the metal, causing plastic deformation and an alteration of the metal grain flow, whereby the metal assumes the shape of the forging die. Note that, in this process, while forged metal material may be preheated, forged metal is never melted or poured. Read More…

ZETWERK provides high quality forged components produced using range of ferrous and non-ferrous alloys. Our in-house forging expertise, together with our production partners, successfully supports demanding programs involving complicated part designs and project requirements. We also perform necessary secondary operations on the forged parts such as finish machining, heat treatment, surface...

All Metals & Forge Group is your ISO9001:2015 and AS9100D registered forging facility. All Metals provides a wide range of materials, products and services, including discs, shafts, sleeves, cylinders, plates, blocks and many other shapes, both stock and custom, satisfying all of their customers’ requirements. Give All Metals & Forge Group a chance to satisfy your needs— you’ll be glad you...

For over 30 years, we have provided metal forged products for a wide variety of industries, including the aerospace, military, food service, medical, and automotive industries. Our customers know they can trust our forgings for quality and affordability.

Although we have over 100 years of experience, we are committed to continually expanding our offerings in all industries. We are not content to remain as we are, but we continually work to improve our products and processes each and every day.

Here at Ken Forging we are a family-owned business who offers our customers high quality forgings. We require no minimum orders and our forgings come in a variety of materials including: stainless steel, carbon steel and more. We provide outstanding technical support and our teams are here to meet your needs by providing same day shipping. You can trust the experts at Ken Forging. Contact us...

More Forging Companies

Forging Applications

The forging process is popular for its ability to create extremely strong and durable metal products upon which users can rely. Forging serves a wide variety of applications that require reliable support of human wellbeing and safety.

Industries that utilize forgings include aerospace, agriculture, automotive, aviation, construction, defense, food processing, industrial manufacturing, mining, oil and gas and shipping.

Products Produced from Forging

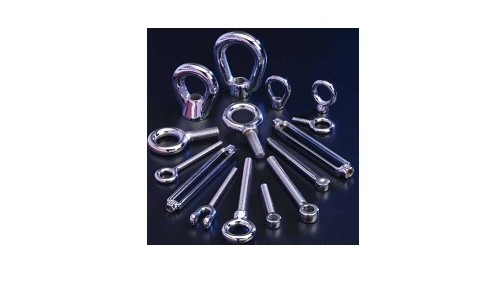

Manufacturers use forging to create metal products of all shapes, sizes and strengths. Some common examples include jewelry, kitchenware, weapons and hardware.

Forgings also serve as components of ships, tractors, engines, tools, airplanes, automobiles, missiles and material handling equipment. They are often featured in these systems and machines as: augers, gears, engine blocks, train tracks, ship valves, brass forged bolts, anchors and more.

History of Forging

People have been forging metal for about as long as they’ve known about metal. Among the earliest examples of forgings, we have today are those forged by the Sumerians around 4500 BC. The Sumerians were the first known civilization to spring up in Mesopotamia. They lived along the Euphrates River Valley and Tigris River Valley areas, in what is now southern Iraq. They forged items using the only metals known to them, bronze and copper, by heating them over fire then beating them with rocks. In this way, they were able to shape tools.

The first furnace, called the bloomery furnace, was constructed during the Iron Age, around 750 BC. The bloomery furnace was made from clay and stone and smiths used it with a bellows in order to make hotter fires. This invention allowed smiths to forge iron. These furnaces were used by a few different societies, including the Nok people who lived in what is now northern Nigeria (500 BC) and in Nubia, Axum and Kush between 1000 BC and 500 BC.

The Chinese began forging and casting iron tools during the 5th and 4th centuries AD. They were also the first people to use blast furnaces and finery forges. Their blast furnace design, invented 1st century AD, was widely used until the 20th century AD. Many other ancient civilizations used blast furnaces including the Celts, Carthaginians, Greeks, and Romans.

The waterwheel, which was invented in Egypt during the 4th century BC or earlier, was adapted by the Greco-Roman world between the 3rd and 1st centuries BC. The waterwheel offered them additional power, which they were able to use for forging. Meanwhile, in 1st century AD China, smiths used water wheels to power the piston bellows they used to forge iron ore.

As early as 900 AD, the Romans were forging metal horseshoes, hand tools, knives and jewelry. During the Dark Ages that followed, the forging of knives and other weapons was incredibly important.

Between the 10th and 12th centuries AD, people were able to urbanize their cities using the water wheel, which let them more easily and effectively forge large iron items. Nevertheless, the forging process did not really evolve until the Industrial Revolution.

During the 1800s, with the help of newer technologies like steam engine power, engineers pushed the forging process to new heights. They found that they could build forges anywhere they wanted, not just by the water. Another big change came in 1856, after Sir Henry Bessemer patented the Bessemer Process for mass producing steel. After this, came the closed die forging, which companies like Colt used to mass produce gun parts.

In the 1930s, engineers finally invented the modern forging press, or forge press. Today, manufacturers perform industrial forging with these presses as well as with hammers. These hammers, unlike the basic blacksmith’s hammer, are powered by mechanisms like: hydraulics, pneumatics, electricity or steam.

Forging Materials Process

The forging process is compatible with a number of ferrous and non-ferrous metals, such as copper, titanium, aluminum, stainless steel, carbon steel, brass and various other alloys, like nickel alloys. All forged materials have different characteristics, and thus offer different benefits to manufacturers and end-users.

Copper forgings are non-sparking, non-magnetic, oxidation resistant, soft and stable at high temperatures. In addition, they conduct electricity well, but without the risk of magnetic interference or sparking.

Titanium material has a larger price tag than most, but it compensates with excellent corrosion resistance, high temperature resistance and a superior strength-to-weight ratio.

Aluminum is lightweight but strong and easy to forge. Aluminum forgings are especially important to aerospace and aviation engineers.

Stainless steel is an alloy steel that offers all the positive qualities of regular steel, like durability, ductility and high strength, as well as the added property of corrosion resistance.

Carbon steel, an iron alloy, responds well to heat treatment and provides good mechanical properties at an economical price.

Brass is an alloy composed primarily of copper and zinc. This material is aesthetically appealing, non-sparking and also has a low level of friction. Brass forging is popular for making parts like: casings, gears, locks, hardware, fittings and bearings.

Nickel alloy boasts oxidation resistance and exceptional stability, even when exposed to high temperatures. Nickel alloy forge operations are usually performed at temperatures above nickel’s recrystallization temperature.

Forging Process Details

Forging uses localized compression forces to form the metal. It is often characterized by the temperature at which it is carried out. Two major types of forging generally used in industries are hot forging and cold forging. In hot forging, the metal must be heated above the temperature of its recrystallization. It is a flexible technique and is commonly used to achieve complex 3D geometries. Cold forging usually involves forging a metal at room temperature, which is usually below its recrystallization. It is a widely used technique in the automotive industry.

Forgings are made through two main forging methods: closed die forging, also known as impression die forging, and open die forging.

Closed die forging, the most common die forging method, involves the use of a hammer and anvil, or hammer alone, and a die or set of dies. During this process, the hammer and anvil press preformed metal blanks, called ingots, into the set of dies, which are shaped as three-dimensional negatives of the part-to-be. Because the hammer and anvil completely cover the work piece, the metal spills into all areas of the die.

In addition to these steps, closed die forging frequently requires a work piece travel through a series of impression cavities that will take it from a rough shape to the final product. The limits of closed die forging are nearly nonexistent; it can produce a countless number of 3D shapes and complex parts with tight tolerances.

Open die forging involves hammering or pressing metal workpieces into their desired shapes with the help of non-closed, simply shaped dies. Dies may be convex, concave or flat. Because it usually takes multiple strikes or presses to get a workpiece to its intended shape, an operator must repeatedly reorient and reposition it, so that the die will fall onto its sections successively.

Open die forging produces forms and shapes that are simpler, like round, hexagonal and rectangular beams, bars and profiles. For this reason, and because open die tooling is less expensive, it fits best with lower volume production and the creation of unique, custom items.

Machinery Used in Forging

Depending on the exact process, forging may involve the operation of a variety of different pieces of machinery. The most common of these include: ovens, drop hammers (hammers and anvils) and forging presses.

Oven

In forging, ovens are heated by gas or coal. Today, gas ovens are much more common than coal ovens. This is because, while coal can create higher temperature fires, it requires more maintenance and it is not environmentally friendly.

Drop Hammer

Hydraulic drop hammers are vertical hammers that, at rest, suspend over a stationary anvil or die with a work piece placed on top of it. They drop the hammer onto the material work piece to deform it.

Forging Press

Forging presses are machines that use a press instead of a hammer to shape the metal. Forging presses may use mechanical power or hydraulic power to work.

Variations and Similar Processes of Forging

Other forging processes include: warm forging, cold forging, hot forging, hand forging, roll forging, roll ring forging, drop forging and press forging.

Warm forging is any forging process during which the metal is heated to 30% above the recrystallization temperature. Warm forging helps manufacturers create products with higher tolerances and less surface scaling. However, it does require higher forming forces and does not allow for as much formability as hot forging.

Cold forging occurs when manufacturers perform forging below a metal’s recrystallization temperature. Often, this is simply room temperature. The cold forge process is best for operation on softer metals like: silver, gold, bronze, copper, brass and platinum. Manufacturers like cold forging because with it they can achieve extremely high tolerances and high tensile strength. Also, cold forging creates no surface scaling. Cold forging can create components that are otherwise not cost-effective through solid bar machining and is the preferred method for high-volume manufacturing.

Forging as a process is classified based on the temperature at which shaping occurs. The broad classification of the same is cold forging carried out at room temperature and hot forging, which is carried out at elevated temperatures (also called red hot temperature in steel). A mid-way between the cold and hot forging is called warm forging, whose working temperature lies between the two. The basic forging setup consists of an anvil on which the object to be shaped is placed, and a hammer is used to strike the object into shape. Each section of the anvil is specifically designed to meet a purpose. For example, the horn is used to introduce a curvature in the object. With some basic knowledge of material physical properties such as malleability and ductility, a farrier can choose the best possible approach to shape the metal.

Since cold forging does not require additional temperature, it is one of the most used methods for forging low-melting point metals. Additionally, steels that are resistant to strain hardening, such as those with a carbon percentage of less 0.05%, can easily be cold forged. Moreover, the shaping of annealed metal parts that may have been previously subject to a heat treatment process but are now being worked upon at room temperature is also classified as cold forging. The primary benefit of using cold forging is to achieve near-net-shape parts that have better grain flow and comparatively better surface finish as opposed to their hot forged variants. However, at the same time, the choice of materials becomes widely limited since a lot of hard steels, which are the most abundantly used alloys, cannot be cold forged. Despite this, cold forging remains a popular choice among farriers due to the overall ease of the process, and perhaps the most abundant use of cold forging is seen in animal farms for horseshoes.

Hot forging operation takes place at a temperature above metal recrystallization temperature. High temperatures make metal much more malleable, so that it is easier to deform. The hot forge process also creates products with more consistent and evenly spread high tensile strength. The most common components made with hot forging techniques include smart balls, screws, nuts, and bolts which are used for a varied range of applications and industries.

Roll forging is a forging process that relies on two grooved cylinders to do the work. During this process, manufacturers pass a heated metal bar in between the grooved cylinders until the bar attains the right dimensions. Usually, manufacturers use roll forging for the production of hardware like leaf springs and axles. Because roll forging does not create flash and it creates parts with high quality grain structure right off the bat, it creates much less waste than many other forging processes.

Roll ring forging is a roll forging operation designed to forge rings. Forged rings are usually produced via an open die forging operation, not a closed die forging operation.

Drop forging is a hammer forge process performed by raising and then dropping a hammer onto a workpiece that is placed on a die. It takes only milliseconds for the hammer drop forge to reach the die. Manufacturers release the hammer until the work piece takes on the form of the die. Drop forming can be performed with an open die or a closed die. Closed-die drop forging involves the use of a die that fully encloses the workpiece.

Press forging involves forming a work piece by slowly and steadily applying pressure either below or above its recrystallization temperature. In this process, the press reaches the workpiece in a matter of seconds. The press forged process allows manufacturers to deform the metal in its entirety. It also allows manufacturers to precision control the forged workpiece’s internal strain.

Composite forging operations are any forging operations that feature the qualities of more than one forging operation. One such example is cold press forging, a composite of cold forging and press forging.

Custom Forging is stronger than its machined parts or equivalent casts. The grain deforms and follows the form of the part as the metal is molded by the forging process so that the grain is constant throughout the part, delivering better and stronger products. It increases the part’s life, which is a significant advantage for highly competitive industries like gas and oil. In comparison with castings or other manufacturing procedures, custom forging provides a lower ultimate cost. Advantages from custom forging include improved strength/rigidity/quality, being cheaper & more reliable, heat treatment provides a better response, providing stronger and better metallurgical properties, a wide product range, consistent composition, cheaper alloys, and no porosity, cavities, or shrinkage.

Forging Benefits

The forging process offers many benefits, including: design flexibility, minimal secondary operations and cost effectiveness., especially when compared to casting and welding. Also, it consistently produces extra strong metal parts and products with very few defects.

Some complimentary benefits of a forged component are eliminating undesired defects and porosity evident in cast metals. Below are the advantages of forging components over casting components:

High Structural Integrity- Forged components have a high degree of structural integrity and are incomparable to other metalworking processes. The reason for this is because these components maintain their uniformity and material structure during the forming process. Forging provides an impressive chemical uniformity through dispersing segregation of non-metallics and alloys. The thermal cycle and deformation process in forging results in grain refinement and metallurgical recrystallization where these enhance the overall impact strength and shear strength of the work part or component.

Forged steel eliminates the issues arising from cast metals where these have problems in porosity or voids that might weaken a part. Forged components have assured structural integrity due to the way these are processed. This results in simplified secondary processes like heat treating and machining, reduction of the need for intensive material inspection, and optimized part strength under extreme load conditions.

Proven Reliability- Due to the way these are fabricated, forged components are spared from issues related to casting components (e.g., the occurrence of cavities, voids, shrinkage, and cold pour defects). These make forged components tougher than the casted ones. Components made from forging can also handle surges of impacts from external forces better than their casted counterpart.

These components have a continuous grain flow and tighter grain structure. Because of this, forged components have exceptional wear resistance without the need for another process to make the material “super hard”. Therefore, forged components are less likely to shatter when impacted by other objects.

Generally Stronger- Forged components are substantially stronger compared to that of the casted materials due to the fact that the grain flows are oriented in a way that the material’s mechanical properties are enhanced (e.g. improved ductility, fatigue resistance, and toughness). Having a compact grain structure on a forged component means that it can have a higher strength to weight ratio. This makes it possible to attain a stronger and tougher component without the need to add in expensive alloys.

From research done by the Industrial and Manufacturing Engineering Department (University of Toledo):

Given that the structure of parts are the same, the findings are as follows: First, Forged components have 26% higher tensile strength than its cast counterpart. Second, Forged components have 37% higher fatigue strength as opposed to that of the casted component. Third, Forged steels can hold significantly higher loads than cast metal before it deforms. Finally, Forged components allow greater deformation before the components fail as compared to that on cast components.

Economical- There are specific reasons as to why forging a component may become more economical than casting a component. Forging has low costs related to the fabrication or manufacturing of medium to large lots. The explanation for this is the expensive costs of forging only come on upfront. Once the tools have been created and the process has been established, components and products can have a high turnaround time, high-speed production, and minimized downtime. This process saves costs in reducing labor requirements and part scrap accumulation by making the entire fabrication process lean.

Things to Consider About Forging

Before agreeing to work with a forging company, you need to make sure that they can meet your needs. For example, many companies offer valuable secondary services, such as: custom die machining, metal stamping, post-forging product testing (ultrasonic testing, radiography, etc.), delivery services and post-delivery support.

To help you find the right manufacturer for you, we’ve put together a list of metal forging companies we trust. Any one of these metal forge companies can deliver you high quality work. Before you begin browsing their offerings, take some time to put together a list of your specifications. Don’t forget to include: your budget, your standard requirements, your delivery preferences and your timeline. Then, peruse the company profiles we’ve provided. Pick out three or four you believe hold the most promise, then reach out to discuss your specifications. After you’ve spoken with each of them, compare and contrast your conversations and their answers, and choose the right one for you.

Check out our Die Castings website

Check out our Investment Castings website

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services